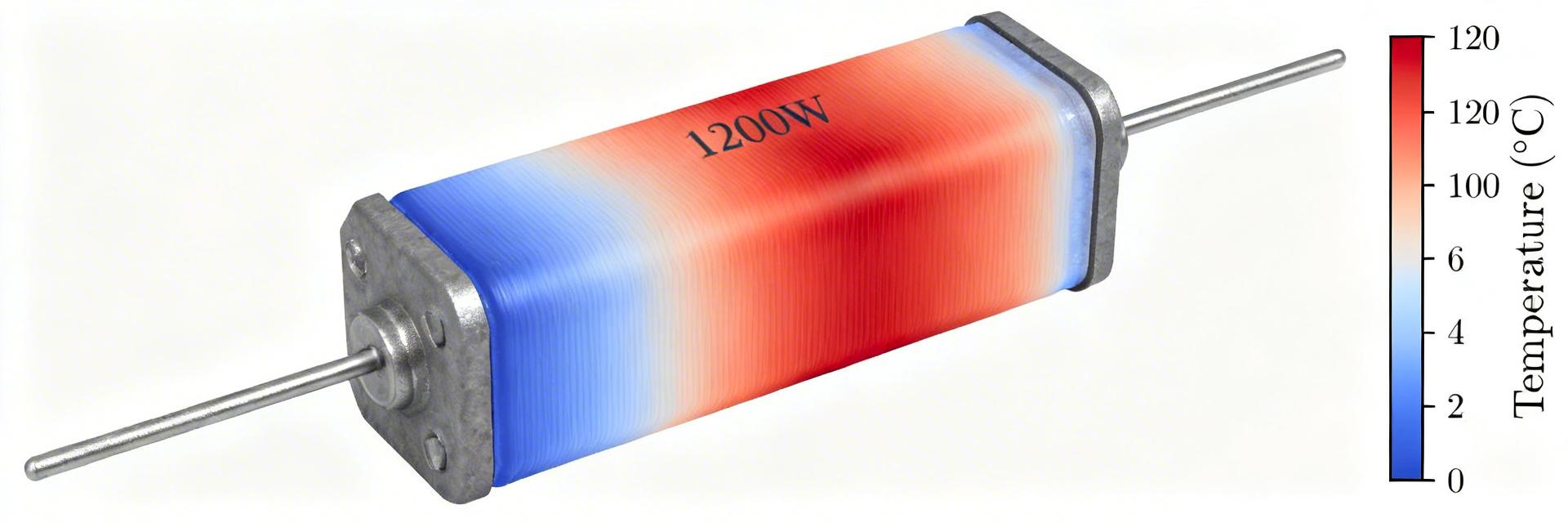

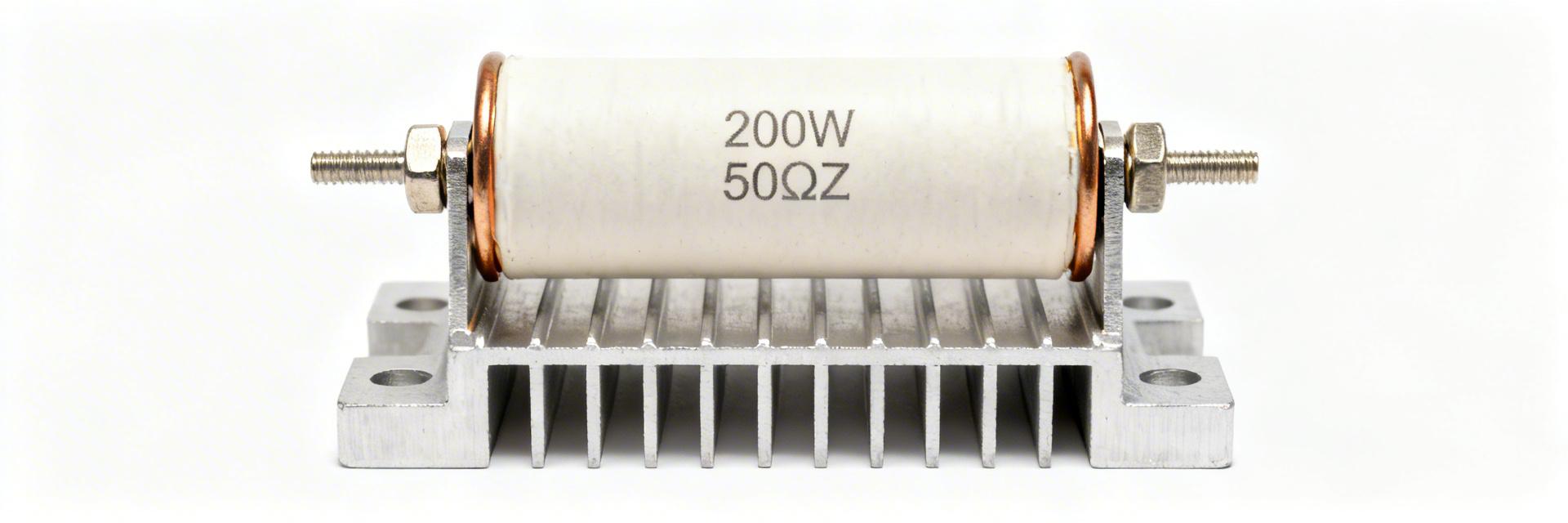

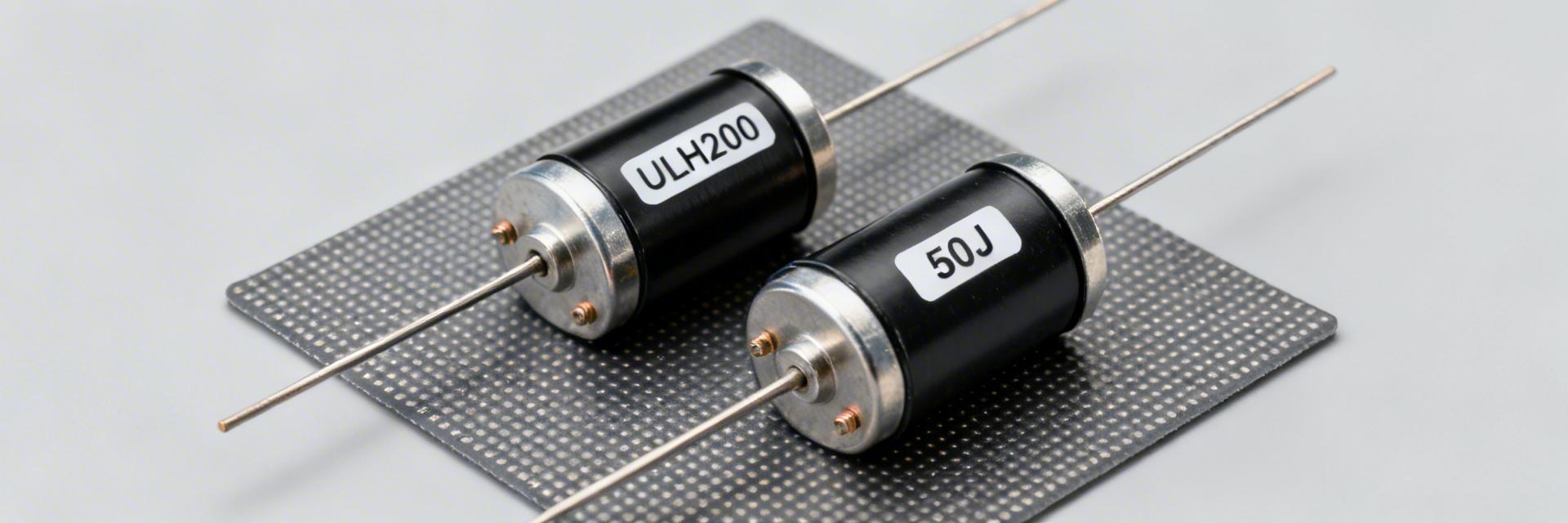

Key Takeaways (Core Insights) Heat Sink Criticality: 200W rating is only achievable with proper metal-to-metal mounting. Mechanical Durability: Aluminum housing provides superior protection and IP-rating potential over ceramic types. Precision Performance: 50Ω resistance with ±1% tolerance ensures stable dynamic braking. Efficiency: Optimized thermal coupling reduces footprint by up to 30% vs. unencapsulated resistors. Point: The ULH 200W 50Ω resistor is a common choice where controlled, repeatable dissipation is required in industrial and test systems. Evidence: Data sheets for ULH‑style metal‑clad, wire‑wound resistors routinely specify 200 W when mounted to a proper heat sink and substantially lower free‑air ratings. Explanation: That split between heat‑sink and free‑air performance is the single most important design discriminator when selecting a resistor for braking, load testing, or continuous power dissipation. Point: This guide focuses on measurable spec checks, thermal sizing, mounting, and field troubleshooting. Evidence: Practical verification steps—case thermocouple readings, steady‑state runs, and IR scans—are emphasized to validate manufacturer ratings in the intended mounting. Explanation: Following these procedures reduces field failures and ensures the resistor operates within its rated limits under representative duty cycles. 200W Peak Capacity Enables high-energy absorption in dynamic braking without increasing system volume. Metal-Clad Housing Extends component lifespan in high-vibration and dusty industrial environments. Low TCR (≤200ppm) Maintains resistance accuracy even as the unit heats up, preventing current drift. 1 — Background: What is the ULH 200W 50Ω resistor? Design & construction Point: The ULH form factor is a metal‑clad, wire‑wound resistor in an aluminum housing filled with thermally conductive cement. Evidence: Typical construction features a wound resistive element on an insulating former, cement or potting for mechanical and thermal coupling, and an extruded or stamped aluminum case. Explanation: That construction yields robust mechanical protection, improved thermal conduction to the case, and stable resistance under high‑power operation compared with unencapsulated elements. Key electrical & mechanical ratings to expect Point: Certain specs must be checked on any candidate part before design. Evidence: Nominal resistance (50 Ω), tolerance (±1% or ±5%), power rating (200 W on specified heat sink; lower free‑air rating), maximum working voltage, TCR (ppm/°C), max case temp, dimensions, weight, and mounting hole pattern. Explanation: Confirming each item ensures compatibility with system voltages, thermal environment, mechanical layout, and safety margins. Spec Name Typical Value ULH 200W Advantage Vs. Standard Ceramic Power Rating 200W (on Heatsink) Higher power density Often Housing Aluminum Clad Excellent Heat Transfer Fragile/Poor Dissipation TCR 50–200 ppm/°C Stable Load Value High drift at temp Max Temp ~125°C Industrial Grade Lower Safety Margin 2 — Complete specs & datasheet overview How to read the datasheet Point: A datasheet contains the authoritative specs and derating behavior that drive design decisions. Evidence: Critical fields include rated power and how it was measured, derating graph, resistance vs. temperature, TCR, tolerance, surge and short‑time overload ratings, insulation and mechanical drawings. Explanation: Read the derating curve and mounting notes carefully: a 200 W rating almost always assumes metal‑to‑metal mounting to a specified sink and defined ambient conditions. 👨💻 Engineer's Pro-Tip: Field Layout "When laying out high-power resistors like the ULH 200W, I always recommend applying a thin layer of thermal grease (0.1mm) between the aluminum case and the chassis. In my experience, skipping this can lead to a 15-20°C increase in case temperature under full load, which significantly shortens component life." — Dr. Elias Vance, Senior Systems Engineer Selection Tip: Always budget for 20% voltage overhead for surge protection. Layout Tip: Keep sensitive control wires at least 50mm away from braking resistors to avoid EMI. 3 — Performance & thermal management Thermal derating & calculations Point: Thermal sizing is arithmetic plus measured verification. Evidence: Use the simplified relation R_th_required = (T_case_max − T_ambient) / P (°C/W). Example: Allowable case 125°C, ambient 40°C, P=200 W → R_th_total ≤ (125−40)/200 = 0.425 °C/W (illustrative). Explanation: Combine the resistor’s internal thermal resistance, interface resistance (thermal pad/compound), and heat‑sink resistance. Validate with case thermocouple and IR camera after 15–30 minutes at steady load. Power Source ULH 200W 50Ω Resistor GND Thermal Interface Material Hand-drawn schematic for illustrative purpose; not a precise engineering diagram. 4 — Installation, safety & compliance Point: Electrical and mechanical wiring practices reduce failures. Evidence: Use insulated lugs, strain relief on flying leads, correct conductor gauge, and rated fusing for both continuous and surge currents. Explanation: Add transient suppression if driving inductive loads, and consider a temperature sensor or thermistor for an overtemp interlock in critical systems. 5 — Typical applications & real-world use cases Dynamic braking & motor drives Point: ULH 200W 50Ω resistors are frequently used for dynamic braking where kinetic energy is converted to heat. Evidence: Key checks include braking duty cycle, time constants, and peak vs continuous power—size the resistor for average energy over the braking interval and thermal recovery time between events. Explanation: Calculate motor inertia energy and compare to resistor thermal capacity and continuous dissipation capability to avoid overheating during repeated braking events. 6 — Practical selection checklist & troubleshooting Selection Checklist Confirm nominal resistance and tolerance (50 Ω ±x). Verify continuous power rating in your mounting (200 W on specified heat sink). Check the derating curve and your ambient conditions. Validate max working voltage and insulation specs. Confirm terminals, mounting pattern, and mechanical fit. Ensure necessary approvals and environmental suitability. Common failure modes & fixes Point: Failures are usually thermal or mechanical. Evidence: Overheating (raise sink or airflow), loose terminals (retorque and use lock washers), resistance drift (inspect for moisture or overheating damage), and thermal‑cycling fatigue (consider higher rating or improved mount). Explanation: Troubleshoot with ambient/loaded resistance checks, IR scans, and visual inspection of the coating and terminals. Summary Point: The ULH 200W 50Ω resistor is a robust metal‑clad, wire‑wound device for energy dissipation tasks but must be specified with its mounting and thermal path in mind. Evidence: Verify datasheet power ratings, derating curves, TCR, and mechanical drawings; perform thermal verification under representative duty cycles. Explanation: Before finalizing a design, document the resistor’s rated power for your mounting, run steady‑state thermal tests, and add monitoring and protective measures as required. Final Integration Checklist: Confirm resistance, tolerance, and listed power with mounting notes. Size heat sink using R_th calculations and verify with thermocouple/IR tests. Follow wiring, torque, and safety recommendations; add fusing and overtemp interlocks. Include datasheet‑specified derating, TCR, and environmental ratings in records.