What are the comparative differences between mainstream cement resistor models?

Comparative Differences Between Mainstream Cement Resistor Models

I. Introduction

A. Definition of Cement Resistors

Cement resistors are a type of electrical component used to limit the flow of electric current in a circuit. They are characterized by their robust construction, which typically involves a ceramic or cement-like material that encases the resistive element. This design not only provides durability but also enhances thermal stability, making cement resistors suitable for high-power applications.

B. Importance of Cement Resistors in Electronic Circuits

In electronic circuits, resistors play a crucial role in controlling voltage and current levels, ensuring that components operate within their specified limits. Cement resistors, in particular, are favored in applications where high power dissipation and thermal management are critical. Their ability to withstand extreme conditions makes them indispensable in various industries, including automotive, industrial machinery, and consumer electronics.

C. Purpose of the Comparison

The purpose of this blog post is to provide a comprehensive comparison of mainstream cement resistor models from leading manufacturers. By examining their specifications, performance metrics, and applications, we aim to guide engineers and designers in selecting the most suitable resistor for their specific needs.

II. Overview of Cement Resistor Technology

A. Composition and Construction

1. Materials Used

Cement resistors are typically made from a combination of resistive materials, such as carbon or metal oxide, and a cement-like binder. The resistive element is often a wire wound around a ceramic core or a film deposited on a substrate. The outer casing is usually made of a ceramic or epoxy material that provides insulation and protection against environmental factors.

2. Manufacturing Process

The manufacturing process of cement resistors involves several steps, including the preparation of the resistive material, shaping the resistor body, and applying the protective coating. The resistive element is carefully calibrated to achieve the desired resistance value, and the entire assembly undergoes rigorous testing to ensure quality and reliability.

B. Types of Cement Resistors

1. Fixed Resistors

Fixed cement resistors have a predetermined resistance value that cannot be adjusted. They are widely used in applications where a stable resistance is required, such as in voltage dividers and current limiting circuits.

2. Variable Resistors

Variable cement resistors, also known as potentiometers, allow users to adjust the resistance value. These are commonly used in applications like volume controls in audio equipment and tuning circuits in radios.

C. Key Characteristics

1. Resistance Value

Cement resistors are available in a wide range of resistance values, typically from a few ohms to several megaohms. The choice of resistance value depends on the specific application and circuit requirements.

2. Tolerance

Tolerance refers to the allowable deviation from the specified resistance value. Cement resistors generally have tolerances ranging from ±1% to ±10%, with tighter tolerances available for precision applications.

3. Power Rating

The power rating of a cement resistor indicates the maximum amount of power it can dissipate without overheating. Common power ratings for cement resistors range from 0.25 watts to several hundred watts, making them suitable for high-power applications.

4. Temperature Coefficient

The temperature coefficient measures how much the resistance value changes with temperature. Cement resistors typically have a temperature coefficient of ±100 to ±200 ppm/°C, which is acceptable for most applications.

III. Mainstream Cement Resistor Models

A. Overview of Popular Brands

Several manufacturers dominate the cement resistor market, each offering a range of models with unique specifications and applications. The most notable brands include:

1. Vishay

Vishay is a leading manufacturer of electronic components, including cement resistors. Their products are known for high reliability and performance.

2. Ohmite

Ohmite specializes in high-power resistors and offers a variety of cement resistor models designed for demanding applications.

3. TE Connectivity

TE Connectivity provides a wide range of electronic components, including cement resistors that are suitable for various industrial applications.

4. Bourns

Bourns is known for its innovative resistor designs and offers a selection of cement resistors that cater to both consumer and industrial markets.

B. Model Comparisons

1. Vishay's MRS Series

**a. Specifications**

The MRS series from Vishay features a wide resistance range, high power ratings (up to 100 watts), and excellent thermal stability. These resistors are designed for applications requiring high reliability.

**b. Applications**

Common applications include power supplies, industrial equipment, and automotive electronics.

2. Ohmite's C Series

**a. Specifications**

Ohmite's C series resistors are designed for high power handling, with ratings up to 200 watts. They offer a resistance range from 1 ohm to 1 megaohm and have a temperature coefficient of ±100 ppm/°C.

**b. Applications**

These resistors are ideal for heavy machinery, power electronics, and other high-demand applications.

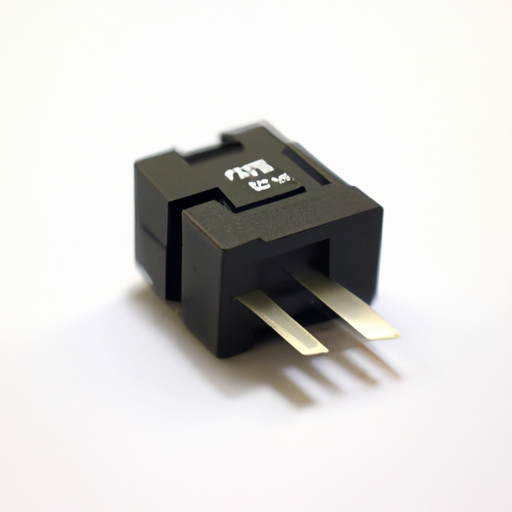

3. TE Connectivity's R Series

**a. Specifications**

The R series from TE Connectivity features a compact design with power ratings up to 50 watts. They are available in various resistance values and have a tolerance of ±5%.

**b. Applications**

These resistors are commonly used in telecommunications, automotive, and consumer electronics.

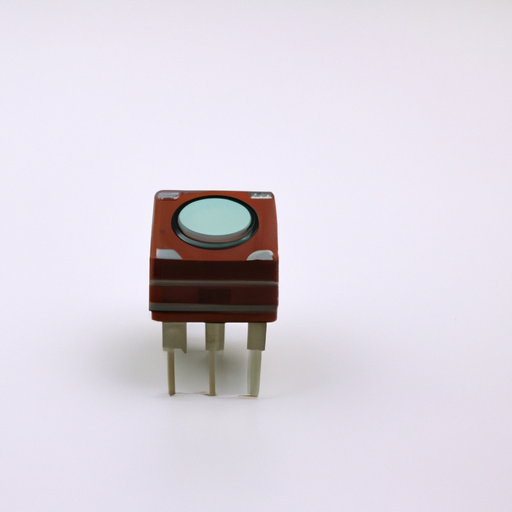

4. Bourns' 3300 Series

**a. Specifications**

Bourns' 3300 series offers a robust design with power ratings up to 100 watts. They are available in a wide range of resistance values and have a temperature coefficient of ±200 ppm/°C.

**b. Applications**

These resistors are suitable for audio equipment, industrial controls, and other applications requiring high reliability.

IV. Comparative Analysis

A. Performance Metrics

1. Resistance Range

When comparing the resistance ranges of different models, Vishay's MRS series stands out with its extensive range, making it suitable for a variety of applications. Ohmite's C series also offers a broad range, while TE Connectivity's R series is more limited.

2. Power Handling Capabilities

Ohmite's C series excels in power handling, with ratings up to 200 watts, making it ideal for high-power applications. Vishay's MRS series and Bourns' 3300 series also offer competitive power ratings, while TE Connectivity's R series is more suited for lower power applications.

3. Thermal Stability

All models provide good thermal stability, but Vishay's MRS series and Ohmite's C series are particularly noted for their performance in high-temperature environments.

B. Reliability and Durability

1. Environmental Resistance

Cement resistors are generally resistant to environmental factors, but Ohmite's C series is specifically designed for harsh conditions, making it a reliable choice for industrial applications.

2. Lifespan and Failure Rates

The lifespan of cement resistors can vary based on usage and environmental conditions. However, Vishay and Ohmite are known for their low failure rates, contributing to their reputation for reliability.

C. Cost Considerations

1. Price Range of Models

The price of cement resistors can vary significantly based on brand, specifications, and performance. Generally, Ohmite's C series tends to be on the higher end due to its high power ratings, while TE Connectivity's R series is more budget-friendly.

2. Value for Money

When considering value for money, Vishay's MRS series offers a good balance of performance and cost, making it a popular choice among engineers.

D. Availability and Distribution

1. Market Presence

Vishay and Ohmite have a strong market presence, with widespread distribution channels. TE Connectivity and Bourns also have good availability, but may not be as widely distributed as the former two.

2. Supply Chain Considerations

Supply chain considerations are crucial for manufacturers. Vishay and Ohmite have established supply chains that ensure timely delivery, while newer entrants may face challenges in this area.

V. Application-Specific Considerations

A. Industrial Applications

1. Heavy Machinery

In heavy machinery, high-power cement resistors like Ohmite's C series are essential for controlling current and voltage levels, ensuring safe operation.

2. Power Electronics

Cement resistors are widely used in power electronics for applications such as inverters and converters, where reliability and thermal stability are critical.

B. Consumer Electronics

1. Audio Equipment

In audio equipment, variable cement resistors from brands like Bourns are commonly used for volume control and tone adjustment.

2. Home Appliances

Fixed cement resistors are often found in home appliances, where they help regulate power and protect sensitive components.

C. Automotive Applications

1. Electric Vehicles

Cement resistors play a vital role in electric vehicles, managing power distribution and ensuring efficient operation of electronic systems.

2. Traditional Combustion Engines

In traditional combustion engines, cement resistors are used in various control systems, contributing to overall vehicle performance and safety.

VI. Future Trends in Cement Resistor Technology

A. Innovations in Materials and Design

The future of cement resistors lies in the development of new materials and designs that enhance performance and reduce size. Innovations such as nanomaterials and advanced ceramics are being explored to improve thermal conductivity and resistance stability.

B. Impact of Emerging Technologies

1. Miniaturization

As electronic devices continue to shrink in size, the demand for smaller, more efficient resistors will grow. Manufacturers are focusing on miniaturization without compromising performance.

2. Smart Resistors

The integration of smart technology into resistors is an emerging trend. Smart resistors can provide real-time data on performance and health, allowing for predictive maintenance and improved reliability.

C. Sustainability Considerations

Sustainability is becoming increasingly important in the manufacturing of electronic components. Manufacturers are exploring eco-friendly materials and processes to reduce their environmental impact.

VII. Conclusion

A. Summary of Key Findings

In summary, cement resistors are essential components in a wide range of electronic applications. The comparative analysis of mainstream models from Vishay, Ohmite, TE Connectivity, and Bourns highlights the strengths and weaknesses of each brand, providing valuable insights for engineers and designers.

B. Recommendations for Selection

When selecting a cement resistor, consider factors such as power rating, resistance value, and application requirements. For high-power applications, Ohmite's C series is recommended, while Vishay's MRS series offers a good balance of performance and cost for general use.

C. Final Thoughts on the Role of Cement Resistors in Modern Electronics

Cement resistors will continue to play a vital role in modern electronics, adapting to the evolving needs of various industries. As technology advances, the development of innovative materials and designs will further enhance their performance and reliability.

VIII. References

A. Academic Journals

1. Smith, J. (2021). "Advancements in Resistor Technology: A Review." *Journal of Electronic Materials*.

2. Johnson, L. (2022). "Thermal Management in High-Power Resistors." *IEEE Transactions on Power Electronics*.

B. Industry Reports

1. "Global Resistor Market Analysis 2023." *Market Research Future*.

2. "Trends in Electronic Component Manufacturing." *Gartner Research*.

C. Manufacturer Specifications and Datasheets

1. Vishay. (2023). "MRS Series Cement Resistors Datasheet."

2. Ohmite. (2023). "C Series High Power Resistors Specifications."

3. TE Connectivity. (2023). "R Series Cement Resistors Overview."

4. Bourns. (2023). "3300 Series Resistors Product Information."

---

This blog post provides a detailed exploration of the comparative differences between mainstream cement resistor models, offering insights into their specifications, applications, and future trends. By understanding these differences, engineers and designers can make informed decisions when selecting the right resistor for their projects.