What are the differences between mainstream non-inductive resistor models?

What are the Differences Between Mainstream Non-Inductive Resistor Models?

I. Introduction

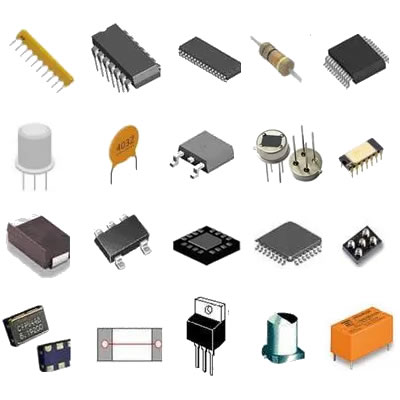

In the world of electronics, resistors play a crucial role in controlling current flow and voltage levels. Among the various types of resistors, non-inductive resistors are particularly important in high-frequency applications where inductance can lead to signal distortion. This blog post aims to explore the differences between mainstream non-inductive resistor models, highlighting their unique characteristics, advantages, and applications.

II. Overview of Resistor Types

A. General Classification of Resistors

Resistors can be broadly classified into two categories: inductive and non-inductive. Inductive resistors, such as wirewound resistors, can introduce unwanted inductance into a circuit, which can be detrimental in high-frequency applications. Non-inductive resistors, on the other hand, are designed to minimize or eliminate inductance, making them ideal for applications where signal integrity is paramount.

B. Common Applications of Non-Inductive Resistors

Non-inductive resistors are commonly used in various applications, including audio equipment, RF circuits, precision measurement devices, and power electronics. Their ability to maintain stable performance at high frequencies makes them essential in these fields.

III. Key Characteristics of Non-Inductive Resistors

When evaluating non-inductive resistors, several key characteristics must be considered:

A. Resistance Value

The resistance value determines how much current will flow through the resistor for a given voltage. Non-inductive resistors are available in a wide range of resistance values to suit different applications.

B. Power Rating

The power rating indicates the maximum amount of power the resistor can dissipate without overheating. Non-inductive resistors are designed to handle varying power levels, making them suitable for both low and high-power applications.

C. Temperature Coefficient

The temperature coefficient measures how much the resistance value changes with temperature. A low temperature coefficient is desirable for precision applications, as it ensures stable performance across a range of temperatures.

D. Tolerance Levels

Tolerance levels indicate the accuracy of the resistor's stated resistance value. Non-inductive resistors come with various tolerance levels, allowing designers to choose components that meet their precision requirements.

E. Noise Characteristics

Noise can affect the performance of electronic circuits, particularly in sensitive applications. Non-inductive resistors are designed to minimize noise, ensuring cleaner signal transmission.

IV. Mainstream Non-Inductive Resistor Models

A. Wirewound Resistors

1. Construction and Design

Wirewound resistors are made by winding a metal wire around a ceramic or fiberglass core. This construction allows for high power ratings and precise resistance values.

2. Advantages and Disadvantages

**Advantages:** High power handling, excellent stability, and precision.

**Disadvantages:** While wirewound resistors can be made non-inductive, they may still exhibit some inductance, especially at high frequencies.

3. Applications

Wirewound resistors are commonly used in power supplies, audio amplifiers, and other applications where high power and precision are required.

B. Thin Film Resistors

1. Construction and Design

Thin film resistors are created by depositing a thin layer of resistive material onto a substrate. This process allows for precise control over resistance values and characteristics.

2. Advantages and Disadvantages

**Advantages:** Excellent stability, low noise, and high precision.

**Disadvantages:** Generally more expensive than other types of resistors.

3. Applications

Thin film resistors are often used in precision measurement devices, instrumentation, and high-frequency applications.

C. Thick Film Resistors

1. Construction and Design

Thick film resistors are made by printing a thick layer of resistive material onto a substrate. This method allows for a wide range of resistance values and power ratings.

2. Advantages and Disadvantages

**Advantages:** Cost-effective, versatile, and available in various resistance values.

**Disadvantages:** Generally less precise than thin film resistors and may have higher noise levels.

3. Applications

Thick film resistors are commonly used in consumer electronics, automotive applications, and general-purpose circuits.

D. Carbon Composition Resistors

1. Construction and Design

Carbon composition resistors are made from a mixture of carbon particles and a binding material. This construction gives them a unique set of characteristics.

2. Advantages and Disadvantages

**Advantages:** Low cost and good performance in high-energy applications.

**Disadvantages:** Higher noise levels and less stability compared to other types of resistors.

3. Applications

Carbon composition resistors are often used in older electronic devices and applications where cost is a primary concern.

E. Metal Film Resistors

1. Construction and Design

Metal film resistors are made by depositing a thin layer of metal onto a substrate, similar to thin film resistors. This construction allows for precise resistance values and low noise.

2. Advantages and Disadvantages

**Advantages:** Excellent stability, low noise, and good temperature coefficients.

**Disadvantages:** Can be more expensive than carbon composition and thick film resistors.

3. Applications

Metal film resistors are widely used in precision applications, including audio equipment, instrumentation, and high-frequency circuits.

V. Comparison of Non-Inductive Resistor Models

A. Performance Metrics

1. Stability and Reliability

Thin film and metal film resistors generally offer superior stability and reliability compared to thick film and carbon composition resistors. This makes them ideal for precision applications.

2. Frequency Response

Thin film and metal film resistors excel in high-frequency applications due to their low inductance and noise characteristics. Wirewound resistors, while capable, may introduce some inductance that can affect performance.

3. Thermal Management

Wirewound resistors typically handle higher power levels better than thin and thick film resistors, making them suitable for applications with significant thermal management requirements.

B. Cost Considerations

Cost is a significant factor when selecting resistors. Carbon composition and thick film resistors are generally more affordable, while thin film and metal film resistors come at a premium due to their precision and performance characteristics.

C. Availability and Sourcing

Most non-inductive resistor types are widely available, but specific models may be harder to source depending on the manufacturer and application requirements.

D. Environmental Impact and Sustainability

As the electronics industry moves towards sustainability, the environmental impact of resistor manufacturing is becoming increasingly important. Thin film and metal film resistors often have a lower environmental footprint compared to carbon composition and thick film resistors.

VI. Choosing the Right Non-Inductive Resistor Model

A. Factors to Consider

When selecting a non-inductive resistor, several factors should be taken into account:

1. Application Requirements

Understanding the specific requirements of the application is crucial. For high-frequency applications, thin film or metal film resistors may be the best choice, while wirewound resistors may be more suitable for high-power applications.

2. Performance Needs

Consider the performance metrics that are most important for your application, such as stability, noise, and thermal management.

3. Budget Constraints

Cost is always a consideration. Determine the budget for the project and select a resistor type that meets both performance and cost requirements.

B. Recommendations for Specific Applications

High-Frequency Applications: Thin film or metal film resistors are recommended for their low inductance and noise characteristics.

Power Applications: Wirewound resistors are ideal for high-power applications due to their robust construction.

General-Purpose Use: Thick film resistors offer a good balance of cost and performance for everyday applications.

VII. Conclusion

In summary, non-inductive resistors are essential components in electronic circuits, particularly in high-frequency applications. Understanding the differences between mainstream non-inductive resistor models—such as wirewound, thin film, thick film, carbon composition, and metal film—can help engineers and designers make informed decisions based on their specific needs. As technology continues to evolve, the future of non-inductive resistor technology will likely focus on improving performance, reducing costs, and enhancing sustainability.

VIII. References

- Academic Journals

- Industry Standards and Guidelines

- Manufacturer Specifications and Datasheets

This comprehensive overview of non-inductive resistor models provides valuable insights for anyone involved in electronics design and engineering, ensuring that the right components are selected for optimal performance.