-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

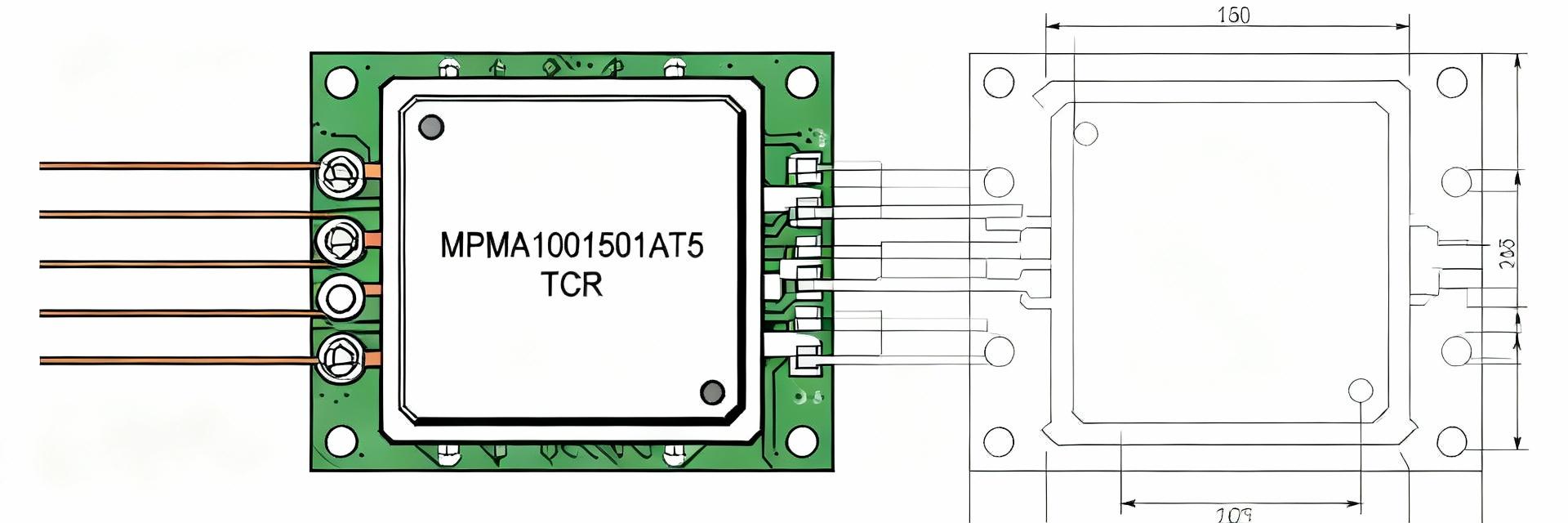

SOMC160110K0GRZ399 datasheet: Full electrical report

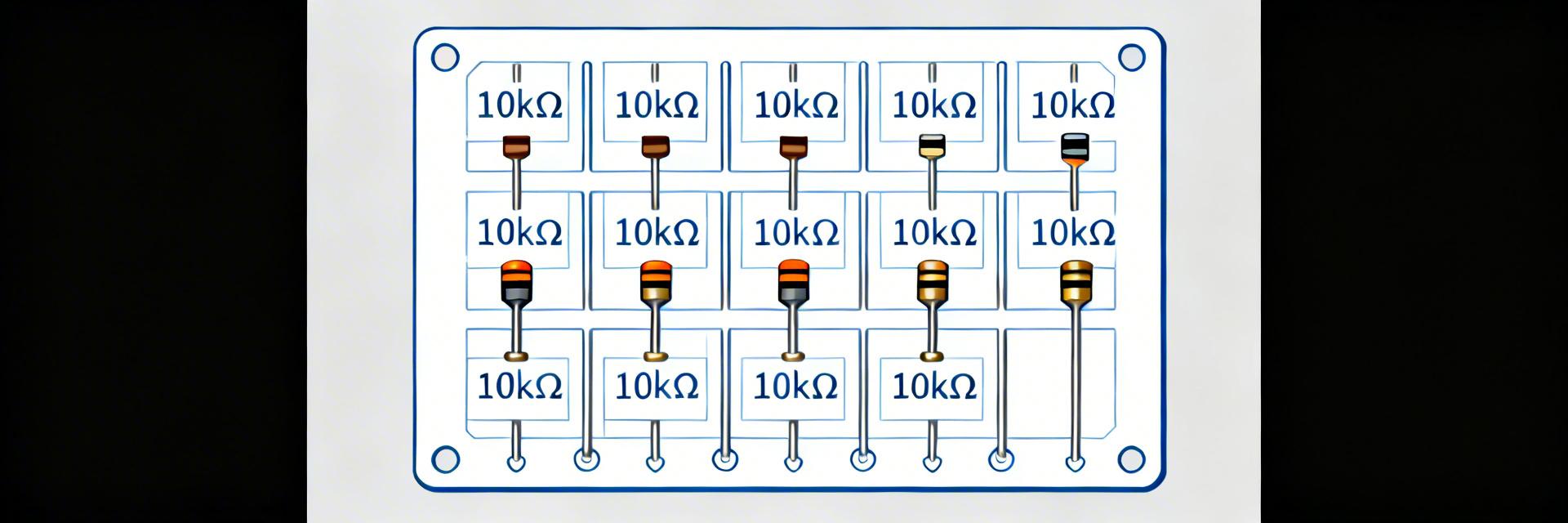

The SOMC160110K0GRZ399 is a 15-element resistor network engineered for precision divider and bussed applications. This comprehensive report details electrical specifications, thermal constraints, and validation procedures essential for high-reliability circuit design.

Product Overview & Key Specifications

Part-Number Meaning & Circuit Options

Point: The part code encodes element count, resistance value, tolerance, and internal topology (bussed vs. isolated).

Evidence: Typical arrays offer a bussed common plus isolated elements in a single package.

Explanation: Simplified pull-ups and common references for system design; isolated elements support independent divider channels. Always verify topology on the datasheet schematic before net assignment.

Detailed Electrical Specifications & Limits

Resistive Performance: Tolerance, TCR & Stability

The ±2% tolerance and 100 ppm/°C TCR determine worst-case behavior. For precise calculations, use the formula:

R_at_T = R_nominal × [1 + (TCR × ΔT)].

• R_drift = 10,000 × [1 + (100e−6 × 60)] = 10,060 Ω

• Worst-case High (+2%): 10,261 Ω

• Worst-case Low (-2%): 9,859 Ω

Power, Voltage and Current Limits

Note: Adjacent element heating reduces effective dissipation. Refer to the derating curve for temperatures above 70°C.

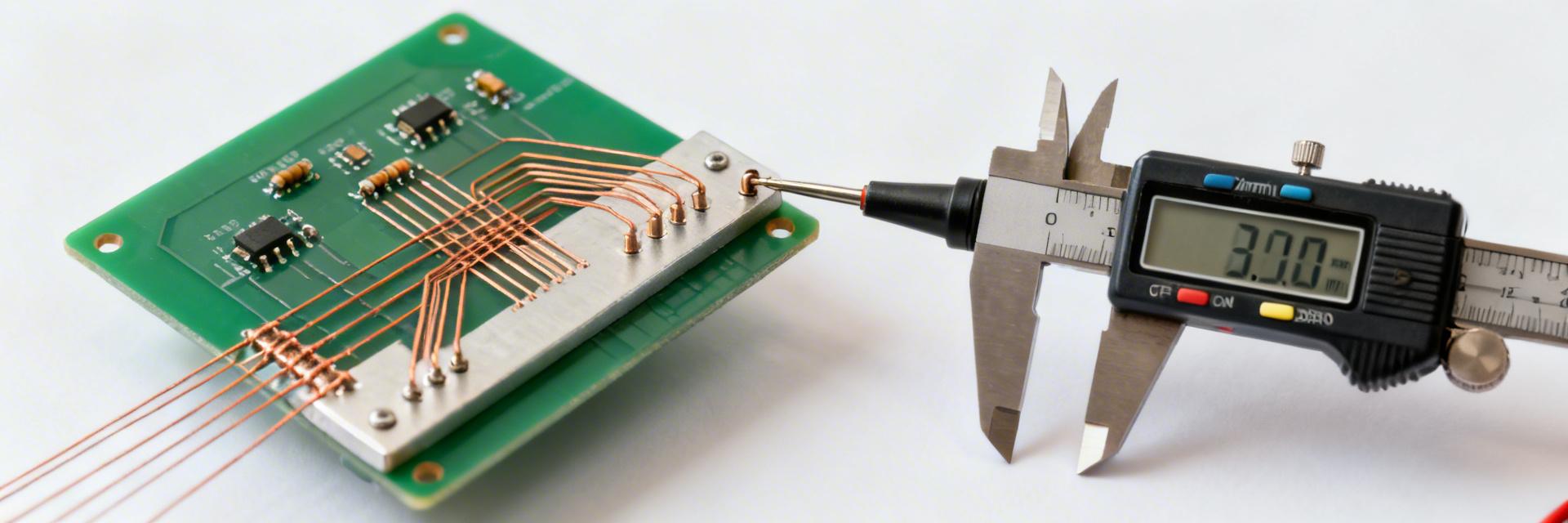

Package, Pinout & Mechanical Data

PCB Footprint Recommendations

- Provide 0.5–1 mm solder fillet clearance.

- Maintain copper pour with thermal relief for dissipation.

- Use thermal vias under the package for improved heat spreading.

Soldering & Reflow

- Lead-free reflow peak: ~245°C.

- Minimize loop area in routing for precision networks.

- Avoid excessive mechanical shear during assembly.

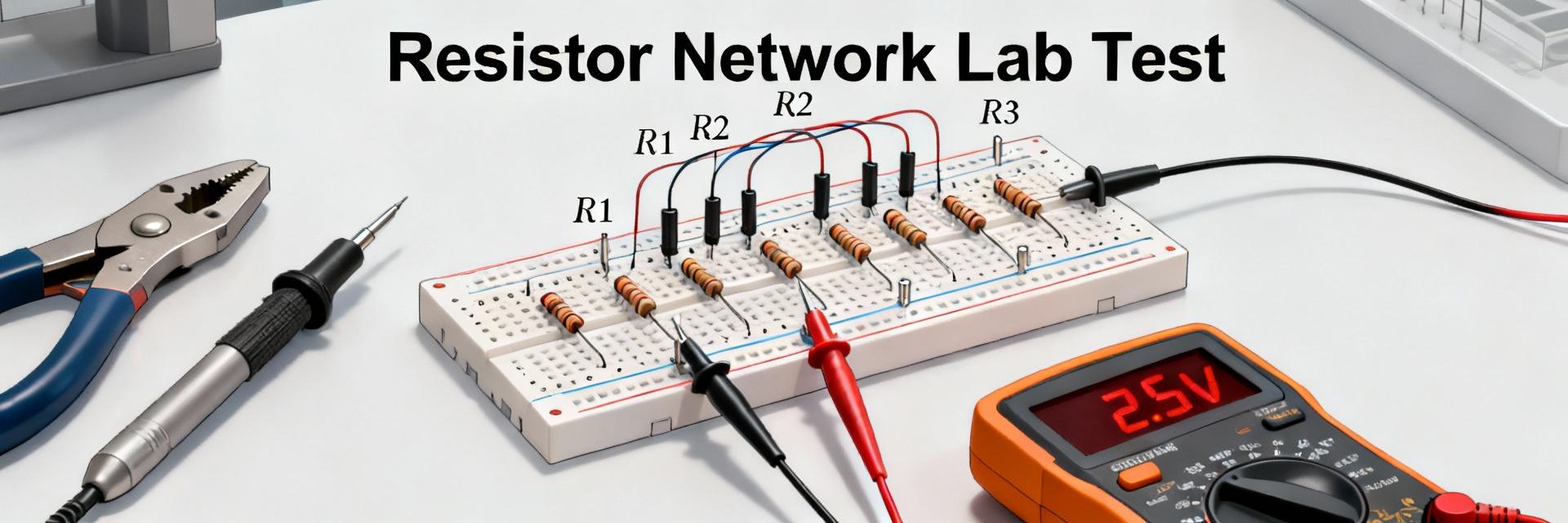

Performance Testing & Validation

Bench Test Procedures: Use a 4-wire resistance measurement for absolute accuracy. Perform a stepped-load power test while monitoring temperature rise via thermocouple to verify thermal stability.

Reliability Data: Load-life stability is the critical metric. If measured drift exceeds ppm specifications, investigate soldering thermal history, PCB mechanical stress, or chemical contamination.

Application Selection Checklist

Key Summary

- • 10 kΩ ±2% Precision: TCR of 100 ppm/°C requires careful accuracy budgeting for high-temp environments.

- • Electrical Limits: I_max ≈ 2.83 mA and V_max ≈ 28.3 V per element; apply linear derating above 70°C.

- • Thermal Design: Use copper pours and thermal vias to ensure long-term reliability and load-life stability.

Frequently Asked Questions

What test steps verify SOMC160110K0GRZ399 resistance and matching? +

How do I compute safe voltage and current limits? +

What if measured drift exceeds the datasheet load-life stability? +

Ready for Implementation?

Retrieve the official SOMC160110K0GRZ399 datasheet PDF and verify your PCB footprint before production.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- SI3402-B-GMR PoE PD Controller: Market & Specs Report

- SI3402-B-GMR Benchmarks: Real PoE Performance Insights

- EFM8BB21F16G Full Datasheet & Pinout: Specs Summary

- CP2102N-A02-GQFN20R Pinout & Footprint: Quick Data Guide

- SI53307-B-GMR Datasheet & CAD Models: Quick Specs Checklist

- SI53361-B-GMR: Latest Specs, Stock Levels & Price Guide

- SI53340-B-GM: Deep Performance Report & Key Metrics

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606